NEC and Ishizaka Sangyo conduct demonstration experiment using local 5G and AI at waste recycling plant

NEC Corporation (Headquarters: Minato-ku, Tokyo; President and CEO: Takayuki Morita; hereafter referred to as

“NEC”) and Ishizaka Sangyo Co., Ltd. (Headquarters: Miyoshi-machi, Saitama Prefecture; Representative Director: Noriko Ishizaka; hereafter referred to as “Ishizaka Sangyo”) conducted a demonstration experiment from October to December 2022 at Ishizaka Sangyo’s recycling plant, aiming to realize a smart plant using local 5G and AI. Intel Corporation (Headquarters: Chiyoda-ku, Tokyo; President and CEO: Kunimasa Suzuki; hereafter referred to as “Intel”), which actively supports local 5G construction and AI implementation, also participated in the demonstration, bringing together the know-how and technologies of each company through cross-industry collaboration.

Labor shortages are a serious issue in the waste disposal industry, and Ishizaka Sangyo’s recycling plant faces challenges such as reducing the risk of collisions when heavy equipment and workers work together in the same yard, and improving the dusty working environment.

NEC and Ishizaka Sangyo began collaborating in July 2020 (Note 1) to realize smart plants. The two companies conducted a demonstration project using laser sensors to sense loading platforms and measure cargo height, as well as remotely assess waste disposal costs using video.

Leveraging the high speed, large capacity, and low latency of local 5G, the project visualized heavy machinery operating status and waste disposal volume in real time, allowing for improvements in work efficiency and risk assessment. Remote control of heavy machinery was also demonstrated to improve work efficiency and reduce manpower, while also creating a safe and secure work environment away from harsh work sites.

[Demonstration Details]

1. Visualization of Work Status Within the Plant:

A local 5G virtualized wireless network (vRAN) environment utilizing Intel Xeon processor-based servers was established within a waste concrete processing plant, and real-time data was collected from cameras and sensors installed in the work area and on heavy machinery. Additionally, a PC equipped with an Intel Core processor was used to monitor on-site work status, quantify work data, and confirm work safety.

1-1. Visualization of the status of heavy equipment and pits within the plant.

We sensed the movements of heavy equipment and the status of the pit, reproducing and visualizing them on a display. By assessing the status in real time, we were able to check for unnecessary heavy equipment movements, leading to the identification of areas for improvement and the consideration of work efficiency improvements. Visualization

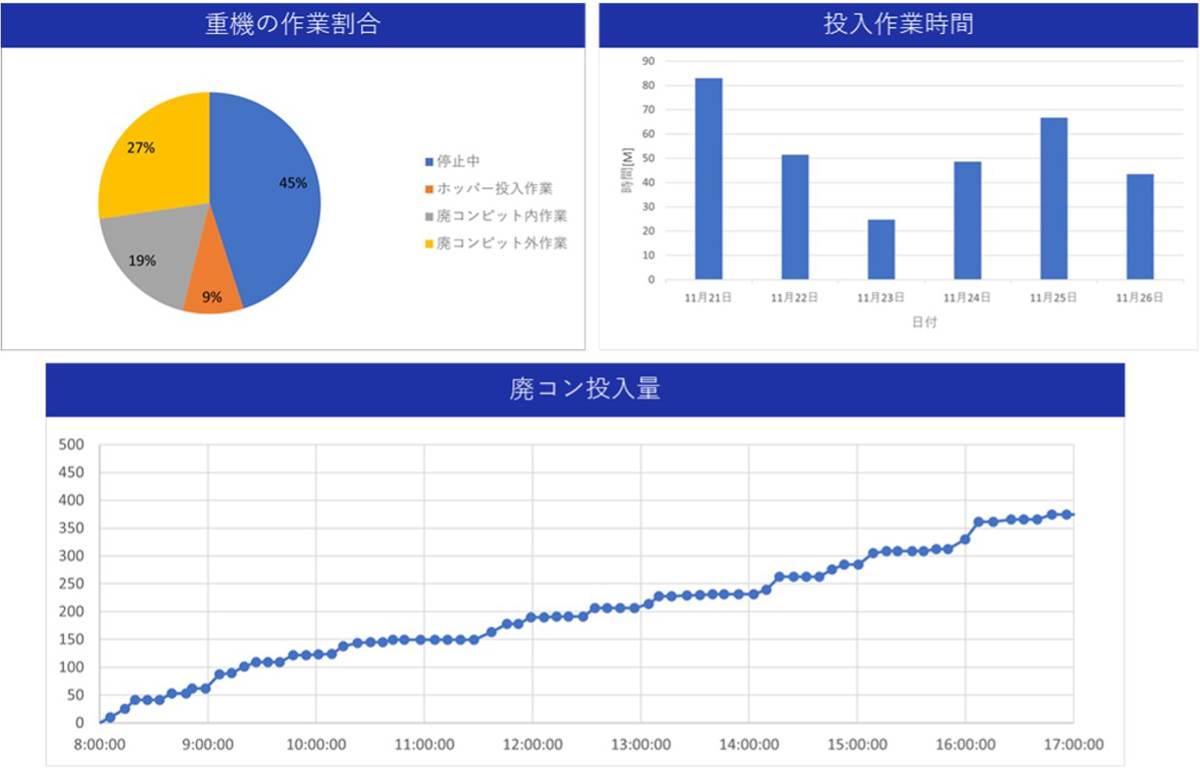

1-2. Visualization of work status

. Using sensors installed on heavy equipment and pits, we quantified and analyzed work status. Specifically, we visualized the ratio of primary tasks (loading waste into hoppers) to indirect tasks (crushing and transshipment), the progress of work from unloading waste to recycling, and the time required for primary waste processing. This allowed us to quantify work status that could only be grasped visually on site. Understanding the amount of waste input per hour, the average number of inputs, and crushing time led to the consideration of measures to improve work efficiency.

Visualization of work status. 1-3.

Visualization of on-site risks . We constantly used video analysis AI to identify people approaching dangerous areas within the plant, and monitored the status of heavy equipment engines to visualize risks. By allowing managers to check the site remotely, it has become possible to reduce the risk of contact accidents and ensure even greater safety.

Visualizing risks in dangerous areas 2.

Remote control of heavy machinery A remote control environment for heavy machinery was created within the mixed waste treatment plant using servers equipped with Intel Xeon processors and wireless technology, creating a safe and secure working environment when dumping mixed waste into the recycling plant. Specifically, footage from eight cameras installed within the plant and on the heavy machinery was processed on a PC equipped with an Intel Core processor, and stable remote control was achieved by utilizing NEC’s Adaptive Remote Control System (Note 2), a network prediction and control AI.

Remote control of heavy machinery

We also collected information on the local 5G radio wave environment in the plant, which is dusty and has a complex installation of equipment such as conveyor belts. By understanding the wireless situation in this complex location, we gained a wealth of knowledge that will help us further expand the area of use and realize new applications that improve efficiency and reduce manpower.

NEC and Ishizaka Sangyo will continue to conduct various demonstrations to promote Ishizaka Sangyo’s smart plant.

As signatories to the Climate Pledge (Note 3), jointly launched by Amazon and Global Optimism, which commits to achieving net-zero carbon emissions by 2040, 10 years ahead of the Paris Agreement, both companies will accelerate their co-creation efforts to reduce carbon emissions.

[Each company’s role]

NEC: Implementing AI and remote/autonomous control technologies, building a local 5G environment, and proposing and demonstrating the use of large amounts of data via local 5G.

Ishizaka Sangyo: Providing knowledge on waste treatment processes and providing the treatment plant for the demonstration experiment.

Intel: Providing various core technologies, including Intel Xeon processors, and supporting the construction of local 5G and AI implementation.

[Company comments]

Through this demonstration, NEC was able to confirm the value of using local 5G within the plant and remotely controlling heavy machinery and visualizing operations in the industrial waste treatment industry. The knowledge gained from the demonstration experiment will be widely shared, and in addition to improving the efficiency of on-site work in a variety of industries with adaptive remote control systems and reducing the labor required with autonomous backhoe driving systems, NEC will also accelerate the provision of “NEC Smart Connectivity” (Note 4), which flexibly utilizes networks and intelligently connects the data necessary for people and things, thereby creating new social value.

Takahiko Amie, Executive Officer, NEC

Through this demonstration experiment, Ishizaka Sangyo has once again become convinced that collaboration between different industries possessing innovative technologies can lead to the emergence of open innovation. The industrial waste disposal industry faces a number of challenges, including accidents and problems caused by plant facilities and heavy machinery, as well as chronic labor shortages. We hope to continue to solve these issues through co-creation utilizing the latest ICT technology, and create an efficient, safe and secure workplace.

Noriko Ishizaka, Representative Director, Ishizaka Sangyo Co., Ltd.

(Note 1) July 14, 2020 Press Release: NEC collaborates with Ishizaka Sangyo to realize smart plants

https://jpn.nec.com/press/202007/20200714_01.html

(Note 2) Adaptive remote control system: A control system that utilizes adaptive remote control technology to achieve high-precision real-time control of robots from remote locations by accurately predicting communication delays in wireless IP communications and implementing proactive predictive control based on the predicted communication delays. https://jpn.nec.com/rd/tg/smc/research/adaptive_remote_control.html

(Note 3) The Climate Pledge:

https://www.theclimatepledge.com

(Note 4) A general term for network services that utilize NEC’s accumulated network technology and knowledge and track record in related solutions. Utilizing networks ranging from 5G to Wi-Fi, it will securely and flexibly connect services and data that have never been connected before in a variety of areas, including social infrastructure, manufacturing, and retail, thereby realizing digital transformation.

A general term for network services that utilize NEC’s accumulated network technology and knowledge and track record in related solutions. Utilizing networks ranging from 5G to Wi-Fi, it will securely and flexibly connect services and data that have never been connected before in a variety of areas, including social infrastructure, manufacturing, and retail, thereby realizing digital transformation.

https://jpn.nec.com/solution/smart_connectivity/index.html

<Contact for customers regarding this matter>

NEC Network Services Planning Division

Email: contact@nwsbu.jp.nec.com

Ishizaka Sangyo Corporate Communications Office

Email: pr@ishizaka-group.co.jp

Please see the press release below.

“NEC and Ishizaka Sangyo conduct demonstration experiment using local 5G and AI at waste recycling plant (PDF)” is available here.

Facility Tour and Training Program

We offer factory tours throughout the year that are open to all visitors.Our programs include tours designed for adults, family-friendly tours for parents and children, as well as tours tailored for companies and organizations.We provide customized courses based on your needs, including the theme, budget, and available time.

Contact Us

For inquiries regarding industrial waste acceptance, media interview requests, or consultations about collaboration and partnerships, please contact us here.